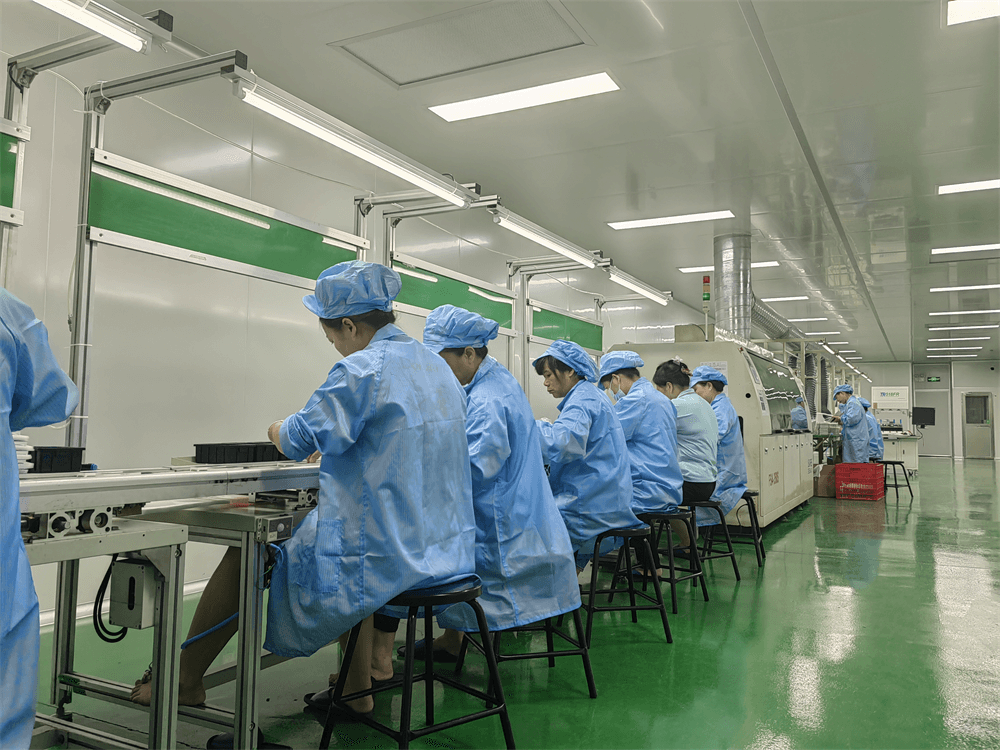

Nowdays the dust-free workshop become a trend in manufacturing industry.

The impact of dust-free workshop on the induction cooker mainly includes the following aspects.

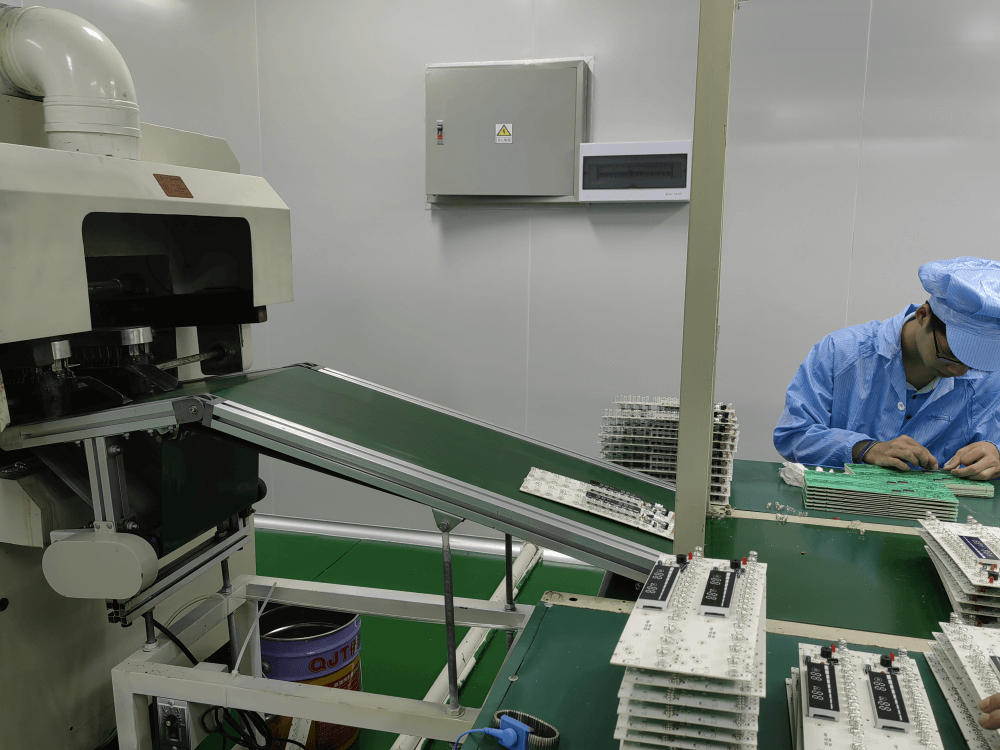

1.Reduce pollution:

The design and operation of the dust-free workshop can effectively reduce the generation and spread of dust, bacteria, microorganisms and other pollutants in the air. If these pollutants enter the induction cooker, it may affect the normal operation of the equipment and the quality of the product. The dust-free workshop reduces the impact of pollutants on the induction cooker by controlling the air quality.

2.Improve product quality

The environment of the dust-free workshop is clean and sterile, which can effectively reduce external impurities from entering the induction hob. This can reduce the probability of product contamination and ensure the production of high-quality products.

3.Extend equipment life

The clean environment of the dust-free workshop can reduce the accumulation of dust, mold and other pollutants inside the induction cooker. If these pollutants accumulate for a long time, they will affect the normal operation of the equipment and even shorten the service life of the equipment. The environment of the dust-free workshop is clean, which can prolong the service life of the induction stove and reduce the cost of maintenance and replacement.

4.Improving the working environment: A clean and hygienic environment in the clean room can improve the working comfort and safety of employees. Working in such an environment, the work efficiency and enthusiasm of employees will also be improved.

To sum up, the impact of the dust-free workshop on the induction cooktops is mainly to reduce pollution, improve product quality, prolong equipment life and improve the working environment. Effective dust-free workshop management can ensure the normal operation of the induction cooker and product quality, improve production efficiency and work safety of employees.

Post time: Aug-03-2023