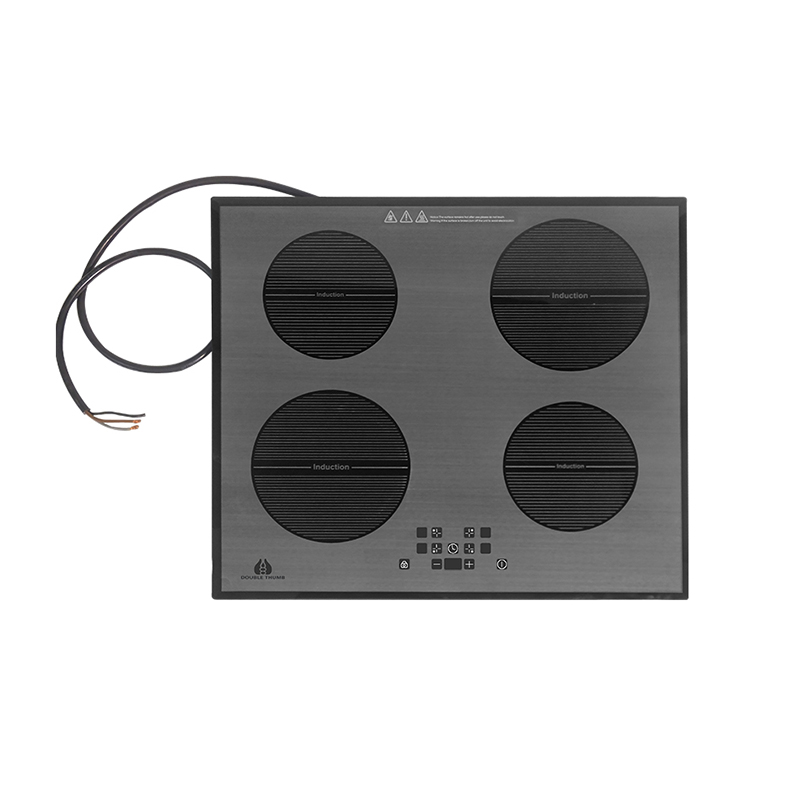

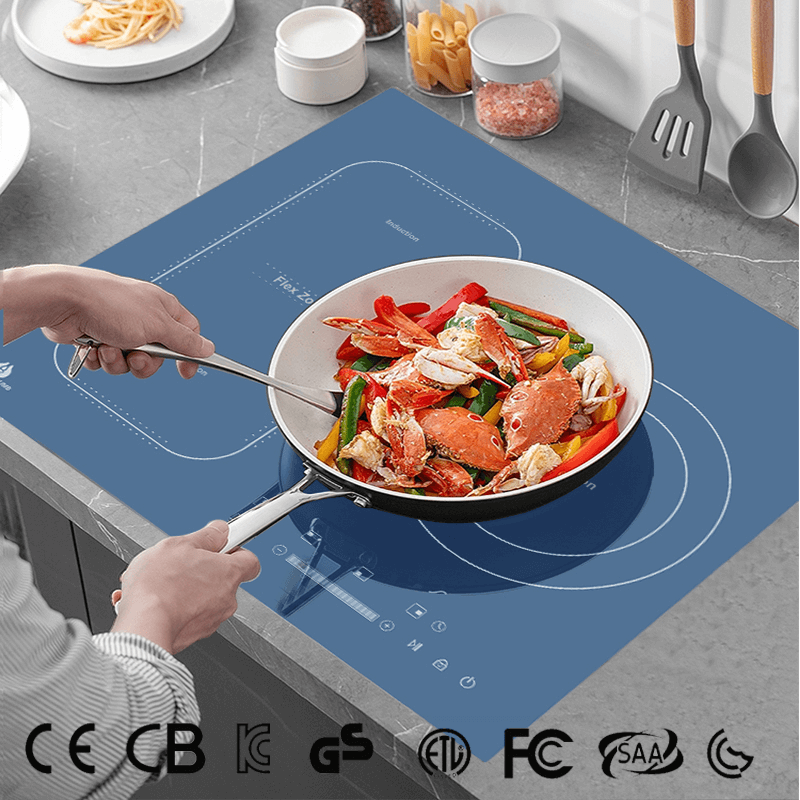

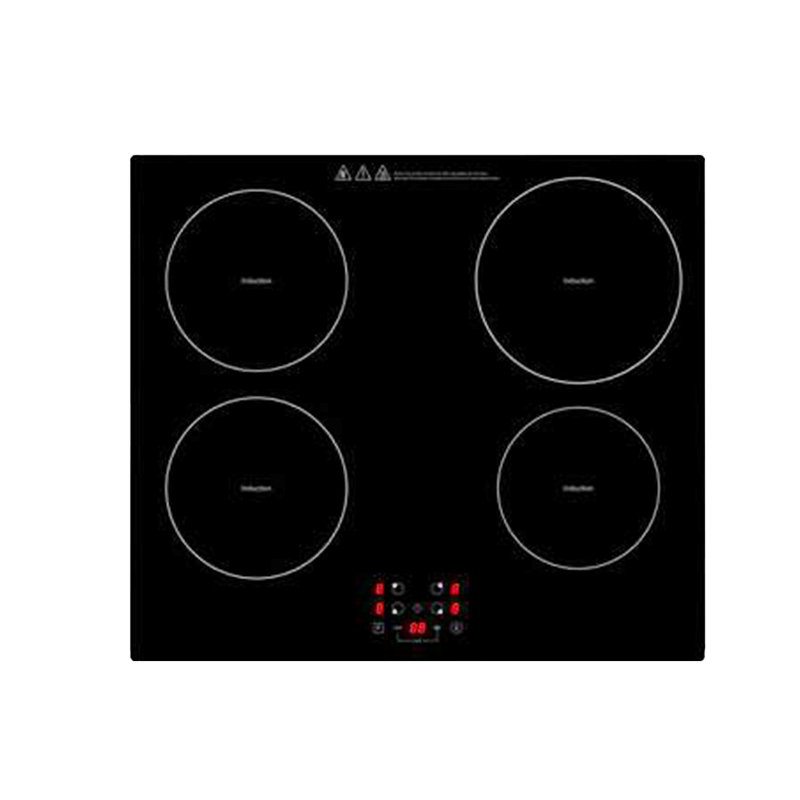

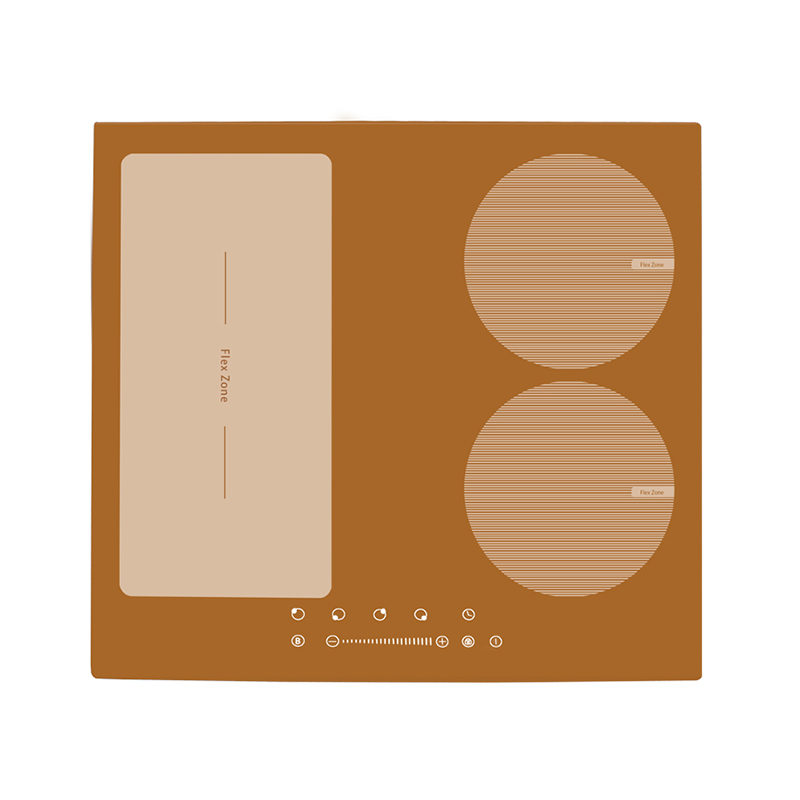

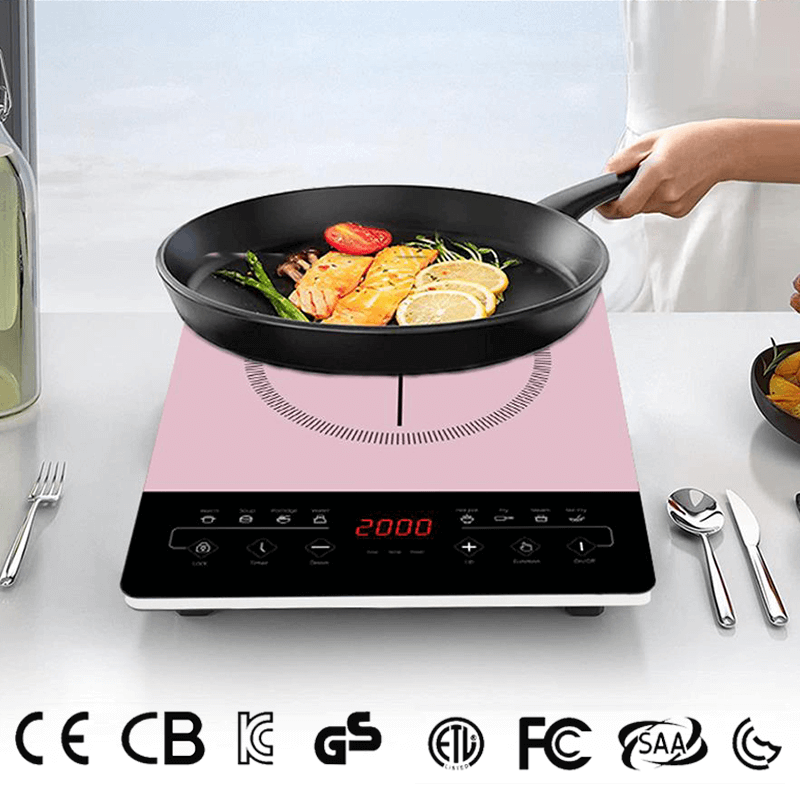

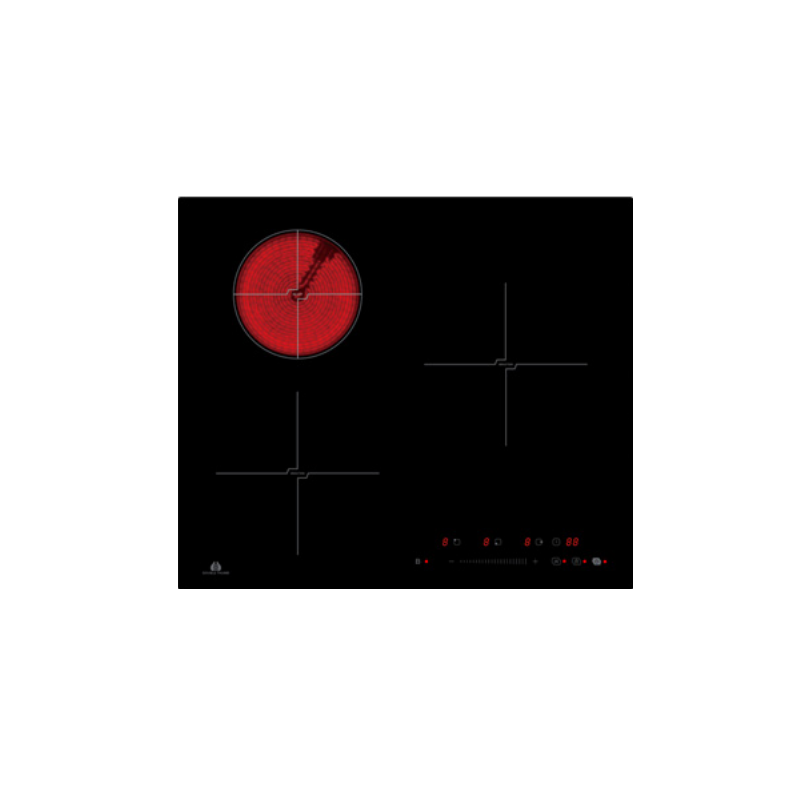

Drop In Induction Hob - Manufacturers, Suppliers, Factory from China

We're committed to furnishing easy,time-saving and money-saving one-sgood purchasing support of consumer for Drop In Induction Hob, Hot Plate Induction Cooker, Glass Top Electric Hot Plate, 4 Hot Plate Stove,Portable Electric Burner For Canning. Green space -- From design to operation, to create a green third space, each store in the store is an important link for Starbucks to integrate into the community and connect the community. Over the past five years, Starbucks China has been designing and building its stores according to green standards, and is committed to creating a greener third space for partners, customers and the community from the perspective of green materials, water-saving electricity and waste disposal. Green materials: More than 98 percent of the building materials and facilities used in the store are locally sourced to reduce the environmental impact of traffic; Use fluorine-free air conditioning system to reduce the damage to the earth's atmosphere; The use of low voc paints encourages in-plant processing to reduce the impact on warehouse air quality. Water saving and energy saving: At present, all stores adopt high-efficiency water-saving devices, which can save water by 35% compared with the national standard; The lighting system all uses LED lights and energy-saving lamps, reaching 15% energy consumption; Waste management: Starbucks China will respond to the government's call by starting waste sorting in Shanghai in July and gradually expanding to more stores in other cities across the country. Green Ambassador -- Green Apron gathers customers and integrates green into life The product will supply to all over the world, such as Europe, America, Australia,Slovakia, Auckland,Bogota, Oslo.We have been concentrating on the quality and updating the production equipment. At present, there are 4 automatic production lines controlled by the production management system to produce the cooking bench made of different materials. A standard production process has been established in strict accordance with 5S Field Management, 8D Exception Handling, and other management laws. Thus, the production efficiency is improved significantly, with a monthly assembly capacity of more than 100,000. After many years of accumulation, we are now experienced in batch production, laying a solid foundation for high quality and high demand.

Related Products

Top Selling Products

-

Phone

-

E-mail

-

Whatsapp

-

Top